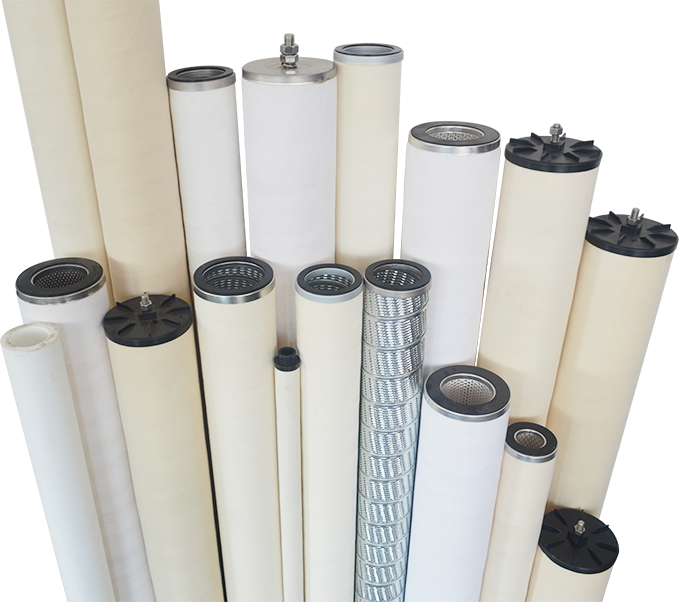

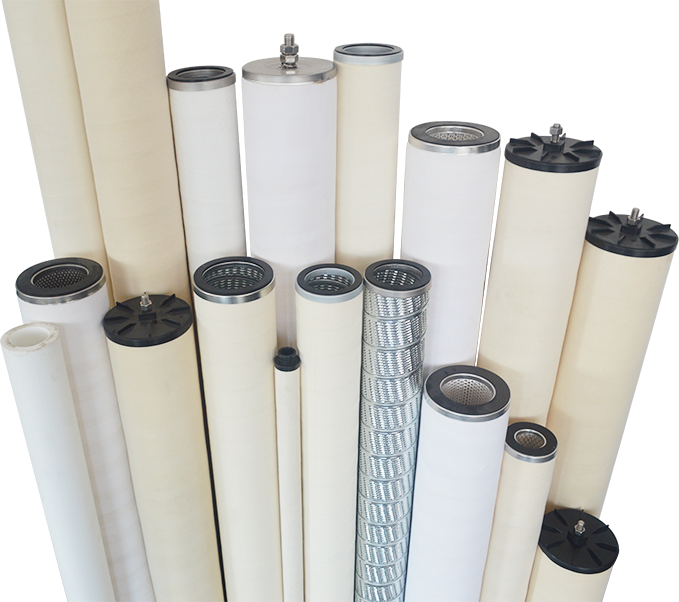

Coalescing separator is mainly designed for liquid-liquid separation. It contains two kinds of filter elements, namely, coalescing filter element and separating filter element. For example, in the oil water removal system, after the oil flows into the coalescence separator, it first flows through the coalescence filter, which filters out solid impurities and coalesces tiny water droplets into larger water droplets. Most of the coalesced water droplets can be separated and removed from the oil by their own weight, and settled into the water collecting tank. Then, the oil flows through the separation filter element. Because the separation filter element has good lipophilicity and hydrophobicity, the water is further separated, and the clean and anhydrous oil flows out of the coalescence separator.