Hydraulic systems power industries like construction, manufacturing, and agriculture, and at their core lies a critical component: the hydraulic filter element. This small but vital part ensures your equipment operates efficiently by keeping hydraulic fluid free of contaminants. In this article, we'll dive into what a hydraulic filter element is, why it's essential, how to maintain it, and how choosing the right one can save you time and money. For top-quality filtration solutions, check out Paierfilter.

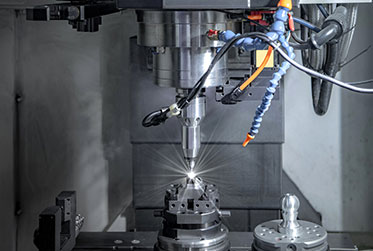

A hydraulic filter element is a replaceable component in a hydraulic system designed to remove contaminants such as dirt, metal particles, dust, and debris from hydraulic fluid. These impurities, if left unfiltered, can damage sensitive components like pumps and valves, leading to reduced efficiency, costly repairs, and downtime.

Hydraulic filter elements are typically made of materials like synthetic fibers, cellulose, or metal mesh, with varying micron ratings to capture particles of different sizes. By maintaining clean fluid, these filters ensure smooth operation and extend the lifespan of your machinery.

Learn more about what a hydraulic filter element is.

Clean hydraulic fluid is the lifeblood of any hydraulic system. Without proper filtration, contaminants can cause:

Component Wear: Abrasive particles erode critical parts, leading to premature failure.

System Inefficiency: Dirty fluid increases friction, reducing performance and increasing energy costs.

Unexpected Downtime: Clogged systems can halt operations, disrupting productivity.

Shorter Equipment Lifespan: Unfiltered systems degrade faster, requiring costly replacements.

A high-quality hydraulic filter element prevents these issues, ensuring reliable performance and long-term savings.

While some hydraulic filter elements are disposable and meant to be replaced, certain types, such as those made from metal mesh, can be cleaned and reused. Cleaning a hydraulic filter element properly can extend its life and maintain system efficiency. Here's a step-by-step guide:

Turn Off the System: Ensure the hydraulic system is powered down and depressurized to avoid accidents.

Remove the Filter Element: Carefully remove the filter from its housing, following your equipment’s manual.

Inspect the Filter: Check for visible damage or excessive clogging. If the filter is torn or heavily damaged, replace it.

Clean the Filter:

Use a compatible cleaning solution (such as a mild solvent or specialized hydraulic filter cleaner) to remove contaminants.

For metal mesh filters, use a soft brush or compressed air to dislodge particles, ensuring you don’t damage the mesh.

Avoid using water or harsh chemicals, as they can degrade the filter material or introduce new contaminants.

Rinse and Dry: Rinse the filter with a clean solvent and allow it to dry completely to prevent moisture from entering the hydraulic system.

Reinstall or Replace: If the filter is clean and undamaged, reinstall it. If it shows signs of wear or reduced efficiency, replace it with a new one.

Test the System: Run the system and check for leaks or performance issues to ensure proper installation.

Note: Always follow manufacturer guidelines, as some filter elements are not designed to be cleaned. For disposable filters, regular replacement is the best practice. Visit Paierfilter for a wide range of high-quality, durable hydraulic filter elements.

Selecting the right hydraulic filter element is crucial for optimal performance. Consider these factors:

System Specifications: Match the filter’s micron rating, flow rate, and pressure capacity to your equipment's requirements.

Operating Environment: Dusty or high-contaminant environments demand higher-efficiency filters.

Quality Matters: Choose filters with advanced filtration media for better contaminant capture and durability.

Maintenance Schedule: Replace or clean filters regularly to prevent clogs and maintain system efficiency.

Explore Paier Filter's extensive range of hydraulic filter elements to find the perfect fit for your machinery.

A hydraulic filter element is a small investment with a big impact, protecting your hydraulic systems from damage, improving efficiency, and reducing maintenance costs. By understanding what a hydraulic filter element is and how to maintain it, you can keep your equipment running smoothly for years to come. Visit Paierfilter today to discover reliable, high-performance filtration solutions tailored to your needs!