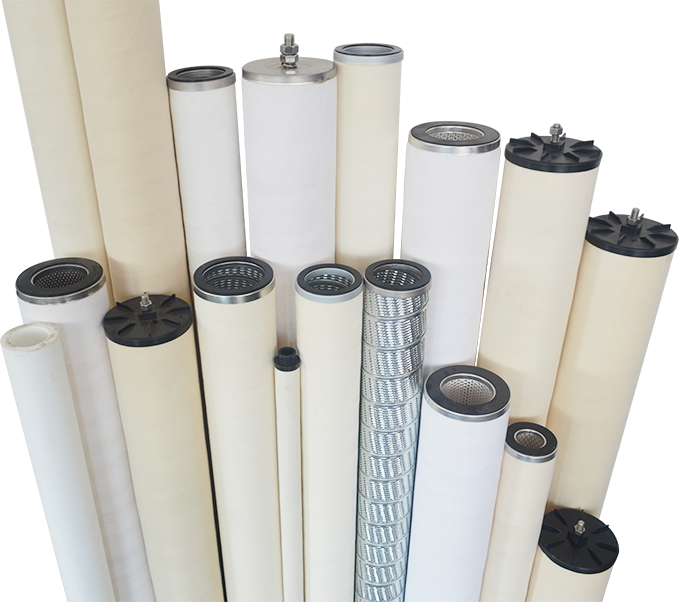

PRJ series coalescing filter cartridges can meet the needs of various filter separators used in fixed and mobile filter facilities. Compliant with API-1581 and GJB610-88 standards, our coalescing cartridge elements are trusted globally and compatible with PECO, FACET, Parker, and more.

As a professional filter cartridge manufacturer, Paier Filter provides high-quality coalescing filter elements and reliable filtration solutions for industrial machinery, fuel systems, or other applications requiring high-quality liquids.

| Parameter | Details |

| Outer Diameter | 100 mm / 150 mm |

| Height | 400 / 500 / 600 / 710 / 840 / 915 / 1120 mm |

| Inner Diameter | 50 mm / 90 mm |

| Mounting Type | Flat Head / Spiral |

| Frame & End Cap Material | Carbon Steel / Stainless Steel / Aluminum Alloy |

| Media Type | Multi-layer Composite Filter Paper, Treated Glass Fiber |

| Standards | API-1581, GJB610-88 |

| Customization | Special metal materials available upon request |

Paier Filter, a leading filter cartridge manufacturer, delivers premium coalescing filter elements and dependable filtration solutions for industrial machinery, fuel systems, and applications demanding high-quality liquid filtration. We have different types of coalescer cartridge elements, offering distinct features and functionalities. At the same time, our coalescing filter cartridge elements have the same functions as other brands. We offer the equivalent of (PECO) coalescing filter cartridge, the equivalent of (Velcon) coalescing filter cartridge, the equivalent of (PALL) coalescing filter cartridge, the equivalent of (JONELL) coalescing filter cartridge and so on.

Find Your Perfect Coalescing Filter Cartridge – Get Expert Guidance Now!

Paier's coalescing filter elements meet the needs of various coalescing filters used in both fixed and mobile facilities.

The Features of Our Coalescing Filter Cartridge Elements:

High Filtration Precision: Utilizes multi-layer composite filter paper for superior filtration accuracy.

Large Dirt Holding Capacity: Provides long service life.

High Flow Density: Reduces the size of the fine filtration system.

Effective Coalescing: Specially treated glass fiber layers ensure excellent coalescing performance.

Standard Compliance: Structure and materials meet API-1581 and GJB610-88 standards.

Wide Range of Specifications: Available in various specifications to suit different fine filtration needs.

Efficient Coalescence: High-density gradient glass fiber effectively coalesces liquid mist and droplets from airflow, offering high filtration accuracy.

Durable Construction: The stable structure prevents dielectric fiber shedding, eliminating environmental contamination and protecting downstream products.

Versatile Compatibility: Suitable for use with a wide range of fluids.

Eco-Friendly: Constructed from 100% synthetic materials, ensuring complete combustion with no residual waste.

Paier's coalescing filter cartridge elements can remove impurities and coalesce water from a variety of substances, including turbine oil, transformer oil, aviation fuel, gasoline, kerosene, diesel, coal tar, and naphtha. When using different coalescing media, they are also suitable for filtering impurities and coalescing water in other hydrocarbon compounds such as LPG, benzene, toluene, xylene, isopropylbenzene, polystyrene, cyclohexane, isopropanol, cyclohexanol, and cyclohexanone. These coalescing filter cartridges provide dual functions of impurity removal and water coalescence, making them essential components in coalescer filtration systems. They meet the needs of various coalescer filters used in both stationary and mobile installations.

*For detailed specifications and availability, please get in touch with us.

| Model | OD | TL | ID | Installation | |||

| MM | IN | MM | IN | MM | IN | ||

| PR-J-Φ100×400 | 100 | 4 | 400 | 16 | 52 | 2 | Flat-head |

| PR-J-Φ100×500 | 100 | 4 | 500 | 20 | 52 | 2 | Flat-head |

| PR-J-Φ100×600 | 100 | 4 | 600 | 24 | 52 | 2 | Flat-head |

| PR-J-Φ150×500 | 150 | 6 | 500 | 20 | 89 | 3 (1/2) | Flat-head |

| PR-J-Φ150×710 | 150 | 6 | 710 | 28 | 89 | 3 (1/2) | Flat-head |

| PR-J-Φ150×840 | 150 | 6 | 840 | 33 | 89 | 3 (1/2) | Flat-head |

| PR-J-Φ150×915 | 150 | 6 | 915 | 36 | 89 | 3 (1/2) | Flat-head |

| PR-J-Φ150×1120 | 150 | 6 | 1120 | 44 | 89 | 3 (1/2) | Flat-head |

| PR-J-Φ150×710L | 150 | 6 | 710 | 28 | 89 | 3 (1/2) | Threaded-end |

| PR-J-Φ150×840L | 150 | 6 | 840 | 33 | 89 | 3 (1/2) | Threaded-end |

| PR-J-Φ150×915L | 150 | 6 | 915 | 36 | 89 | 3 (1/2) | Threaded-end |

| PR-J-Φ150×1120L | 150 | 6 | 1120 | 44 | 89 | 3 (1/2) | Threaded-end |

Coalescer filter elements play a crucial role in the fuel and diesel industry by removing water or moisture contamination. When fuel or diesel is stored or transported, it can come into contact with humid air, resulting in the formation of water droplets. These water droplets can cause corrosion, reduce fuel efficiency, and lead to engine damage.

Coalescer filter elements employ a unique design that utilizes filtration media with hydrophobic properties. As the fuel or diesel flows through the filter element, the hydrophobic media captures and merges small water droplets, causing them to coalesce into larger droplets.

In natural gas processing and transmission, coalescer filter elements are utilized to remove liquid and solid contaminants from the gas stream. Natural gas often contains moisture, hydrocarbon liquids, and particulate matter, which can damage equipment, reduce efficiency, and compromise the quality of the gas.

Coalescer filter elements are also used in the filtration of chemical materials to separate immiscible liquids or remove liquid impurities. In chemical processes, it is often essential to separate different liquid phases or remove contaminants that can affect the quality or performance of the final product.

Coalescing filter element is made of a variety of composite materials by special technology, which has hydrophilic characteristics.

A coalescing filter element is a type of filter used to remove liquid aerosols, oil mist, and other fine particulate matter from a gas stream. The element typically consists of multiple layers of media, including a pre-filter and a coalescing layer.

The pre filter cartridge captures larger particles and protects the coalescing layer, which is designed to merge small liquid droplets into larger ones. As the droplets coalesce, they become heavier and fall out of the gas stream, allowing for their removal through a drain.

Coalescing filter elements are commonly used in compressed air systems, where they help protect downstream equipment from damage and prevent contamination of the final product. They can also be used in industrial processes, such as natural gas and petroleum refining, to remove impurities and improve product quality.

Know more about Coalescing Filter Element: Coalescing Filter Elements: Your Guide to Cleaner Air and Gas Systems

The coalescing filter core mainly selects the surface-treated glass fiber or polyester fiber as coalescing medium, and the structure of the filter material is specially designed to make the filter medium have good coalescing performance. The filtration accuracy can reach 0.1 μ m.

Coalescing filter elements are made from a variety of materials, depending on the specific application and the properties of the gas stream being filtered. The coalescing layer is typically made from materials such as borosilicate glass fibers, polyester fibers, or polypropylene fibers that have been treated to be hydrophobic (water-repellent) or oleophobic (oil-repellent) to facilitate coalescence of the liquid droplets.

The pre-filter layer, which is used to capture larger particles and protect the coalescing layer, may be made from materials such as cellulose fibers, synthetic fibers, or wire mesh.

The choice of materials will depend on factors such as the operating temperature and pressure, the composition of the gas stream, and the required level of filtration efficiency.

The main function of a coalescer cartridge is to remove liquid aerosols, oil mist, and other fine particulate matter from a gas stream. This is achieved through a process called coalescence, which involves merging small liquid droplets into larger ones that are heavy enough to fall out of the gas stream.

Specifically, the functions of a coalescer element include:

Removing liquid aerosols: The coalescing layer of the filter captures liquid droplets that are suspended in the gas stream and merges them into larger droplets that can be removed through a drain.

Removing oil mist: In applications where oil mist is present, the coalescing element can remove the mist from the gas stream and prevent it from causing damage to downstream equipment or contaminating the final product.

Filtering out fine particulate matter: The pre-filter layer of the coalescing filter element captures larger particles that may be present in the gas stream, preventing them from reaching the coalescing layer and reducing its effectiveness as well as playing a cleaning effect.

Protecting downstream equipment: By removing liquid aerosols, oil mist, and particulate matter from the gas stream, the coalescing filter element helps protect downstream equipment from damage and minimize maintenance requirements.

Aggregate dispersed small water droplets into large water droplets.

In addition, it is mainly suitable for fuel, gasoline, diesel oil, stone tar, liquefied petroleum gas, etc., as well as low-viscosity hydraulic oil and lubricating oil.

Overall, the function of a coalescing filter element is to improve the quality of the gas stream by removing contaminants that could cause problems downstream.

The efficiency of a coalescing filter element can be improved by considering several factors such as using a prefilter to remove larger contaminants, optimizing the flow rate to ensure sufficient contact time, selecting appropriate filter media and materials, maintaining proper differential pressure, and ensuring proper filter element sizing for the application. These factors collectively contribute to enhanced efficiency and performance of the coalescing filter element.

When replacing a replacement filter, several precautions should be taken for a successful installation. These include carefully following the manufacturer's installation instructions and steps, preparing the installation area by ensuring cleanliness and removing debris, turning off the power supply to prevent accidental activation, and adhering to safety guidelines. It is important to handle the filter with care, align it correctly, and securely tighten it to prevent leaks. Finally, post-installation checks should be performed to ensure proper sealing and system functionality.

The filter element should be replaced under various circumstances to ensure optimal system performance. These include an increase in pressure drop across the filter, reduced flow rates, decreased filtration efficiency, or reaching the manufacturer's recommended service life. Timely replacement of the filter element is crucial to maintain effective contaminant removal, prevent system damage, improve energy efficiency, and prolong the lifespan of other system components. Regular filter element replacement is essential for reliable and efficient operation of filtration systems.