Separating oil and water is a critical process in industries such as manufacturing, oil and gas, automotive, and wastewater treatment. These two liquids, due to their differing densities and chemical properties, often mix during industrial processes, creating challenges for disposal, recycling, or reuse. Effective oil-water separation ensures compliance with environmental regulations, protects equipment, and enhances operational efficiency. At Paier, we specialize in advanced filtration solutions, including coalescing and separation filter elements, designed to tackle these challenges with precision.

In this article, we'll explore the principles of oil-water separation using filtration, the role of specialized filter elements, and how Paier's cutting-edge technology can help your business achieve clean, efficient results.

Oil and water mixtures can cause significant issues in industrial settings. For example:

Environmental Compliance: Releasing oily wastewater can violate environmental regulations, leading to fines or operational shutdowns.

Equipment Protection: Oil contamination in hydraulic systems or machinery can cause corrosion and reduce equipment lifespan.

Cost Savings: Efficient separation allows for oil recovery and reuse, reducing waste and operational costs.

Filtration, particularly through coalescing and separation filter elements, is one of the most effective methods to address these issues. By leveraging the different specific gravities and chemical properties of oil and water, filtration systems can achieve high-purity separation.

The principle behind oil-water separation through filtration lies in exploiting the physical and chemical differences between oil and water. Water is denser and polar, while oil is less dense and non-polar, allowing specialized filters to isolate one from the other. The process typically involves two key stages: coalescence and separation.

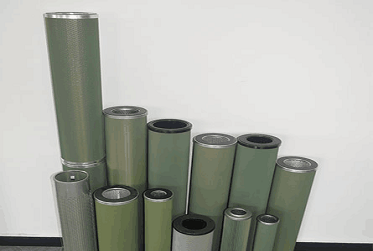

Coalescing filter elements are designed to capture and aggregate small water droplets suspended in oil. As the oil-water mixture passes through the coalescing filter, tiny water droplets combine into larger droplets, making them easier to separate. Paier's coalescing filter cartridges are engineered to remove impurities and coalesce water from various substances, such as turbine oil, transformer oil, and hydraulic oil, ensuring high efficiency.

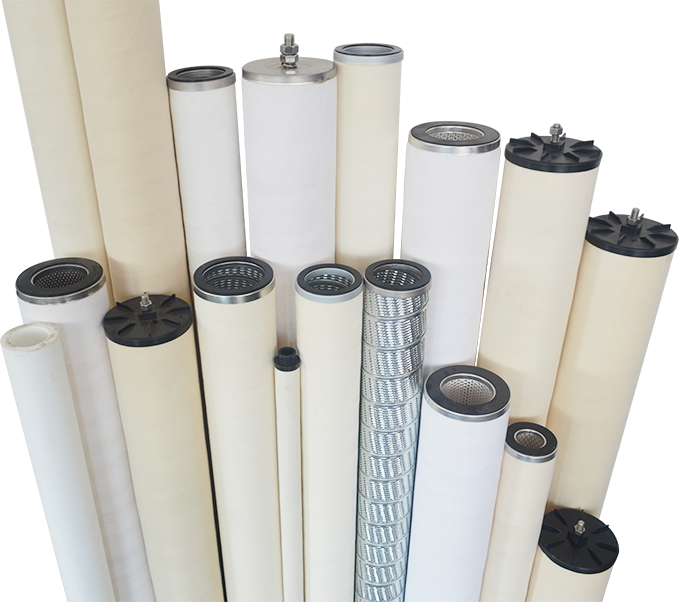

Once water droplets are coalesced, the mixture flows through a separation filter element. This filter is designed with lipophilic (oil-attracting) and hydrophobic (water-repelling) properties, allowing oil to pass through while blocking water droplets. The result is clean, anhydrous oil ready for reuse or safe disposal. Paier's separation filter elements are highly effective in achieving this final stage of purification.

Initial Filtration: The mixture enters the filtration system, where the coalescing filter element traps solid contaminants and begins aggregating water droplets.

Coalescence: Small water droplets merge into larger ones as they pass through the coalescing filter.

Separation: The mixture moves to the separation filter element, which allows oil to pass while retaining water.

Output: Clean oil is collected, and separated water is diverted for treatment or disposal.

This two-stage process ensures maximum efficiency and purity, making it ideal for industries requiring high-performance filtration.

At Paier, we understand the unique demands of oil-water separation. Our filtration products, including coalescing and separation filter elements, are designed to deliver:

High Efficiency: Our filters remove even trace amounts of water and impurities, ensuring clean oil output.

Durability: Built to withstand harsh industrial environments, Paier's filter elements offer long-lasting performance.

Custom Solutions: We provide tailored filtration systems to meet the specific needs of your industry, from hydraulic systems to wastewater treatment.

Environmental Compliance: Our solutions help you meet stringent regulatory standards by ensuring effective separation and waste management.

Paier's filtration technology is used across a wide range of industries, including:

Oil and Gas: Removing water from crude oil or lubricants to improve quality and protect equipment.

Automotive: Ensuring clean hydraulic fluids in manufacturing processes.

Wastewater Treatment: Treating oily wastewater to meet environmental discharge standards.

Power Generation: Protecting turbines and transformers by removing water from oils.

To maximize the efficiency of your filtration system:

Regular Maintenance: Clean or replace filter elements as recommended to maintain performance. Paier's cleaning techniques, such as reverse water inflow, can extend filter life.

Choose the Right Filter: Select coalescing and separation filter elements designed for your specific application and fluid type.

Monitor System Performance: Regularly check for pressure drops or reduced flow rates, which may indicate filter clogging.

Partner with Experts: Work with trusted providers like Paier to ensure your filtration system is optimized for your needs.

Paier is a leader in filtration technology, offering innovative solutions for oil-water separation. Our coalescing and separation filter elements are designed with precision to deliver clean, high-quality results. Whether you're dealing with hydraulic fluids, transformer oils, or industrial wastewater, Paier's products ensure efficiency, reliability, and compliance.

Ready to enhance your oil-water separation process? Explore Paier's range of filtration solutions at www.paierfilter.com and contact our team for customized recommendations.

Separating oil and water using filtration is a proven, efficient method for addressing industrial challenges. By leveraging coalescing and separation filter elements, businesses can achieve clean oil, protect equipment, and meet environmental standards. Paier's advanced filtration solutions are designed to deliver superior performance, making us the go-to choice for industries worldwide. Visit Paier today to learn how we can support your oil-water separation needs.