In today's fast-paced industrial landscape, compressed air systems are the lifeblood of countless processes, from manufacturing assembly lines to precision automation, automotive painting, food and beverage packaging, and even medical device production. The demand for high-quality compressed air has never been greater, with the global compressed air market projected to exceed $35 billion by 2028, according to recent industry analyses. Yet, achieving truly clean, dry, and oil-free air remains a persistent challenge. Compressors inherently introduce contaminants like lubricating oil aerosols, water vapor, and fine particulates into the airstream, which can wreak havoc on downstream equipment and product quality.

This is where coalescing filter elements emerge as indispensable heroes. These advanced filtration solutions are engineered to capture and remove submicron oil aerosols, water mists, and solid particles, ensuring compliance with stringent standards like ISO 8573. By coalescing tiny droplets into larger, drainable ones, these filters deliver exceptionally clean air—often to Class 1 levels (0.01 mg/m³ oil content)—protecting pneumatic tools, valves, and cylinders from premature wear. The benefits extend far beyond equipment longevity: facilities report up to 20% reductions in energy consumption and maintenance expenses, alongside enhanced product consistency and regulatory adherence.

Coalescing filtration represents a sophisticated evolution in air purification, leveraging physics to achieve superior contaminant removal without excessive pressure loss. At its core, a coalescing filter element is a multi-layered cartridge, typically constructed from borosilicate glass microfiber, synthetic polymers, or coalescing media impregnated with oleophobic treatments. These materials create a tortuous path for airflow, maximizing contact time with contaminants.

The filtration process operates through a three-stage mechanism:

Impingement and Diffusion: Incoming compressed air, laden with oil vapors (from 1-5 µm aerosols) and moisture, passes through the filter media. Inertial impingement causes larger droplets to crash into fibers, while Brownian diffusion captures ultrafine particles (<0.1 µm). This initial capture stage removes up to 99% of gross contaminants.

Coalescence: The magic happens here—trapped micro-droplets migrate along fiber surfaces, drawn together by surface tension and van der Waals forces. They merge into progressively larger droplets (up to 300 µm), preventing re-entrainment and ensuring efficient separation. This "agglomeration" effect is what sets coalescing filters apart from standard particulate filters, which merely block rather than transform contaminants.

Drainage and Separation: Gravity and a hydrophobic barrier at the media's base direct coalesced liquids downward into a sump for automatic drainage. The result? Outlet air with residual oil content as low as 0.003 mg/m³ and pressure drops under 0.35 bar, preserving compressor efficiency.

Unlike desiccant or membrane dryers, which target only moisture, coalescing elements address the full spectrum of compressor-generated pollutants. They integrate seamlessly into multi-stage filtration trains: pre-filters handle rust and bulk liquids, coalescers tackle aerosols, and after-filters polish for absolute cleanliness. Reputable brands like Parker, Donaldson, and SMC provide standardized housings, but for cost-conscious operations, Paier Filter delivers OEM-equivalent coalescing filter element replacements. Crafted with premium imported media, these elements withstand pressures up to 16 bar and temperatures from -20°C to 80°C, offering performance parity at 40-60% lower costs.

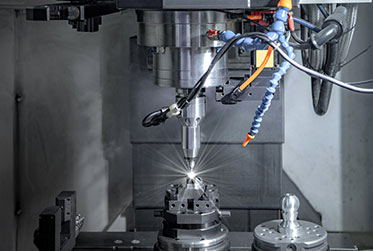

Compressed air systems span a wide array of industries, each with unique purity demands. Coalescing filters adapt effortlessly, installed post-compressor and pre-dryer to intercept contaminants early.

In manufacturing and automation, pneumatic cylinders, grippers, and valves rely on oil-free air to avoid sticky seals and erratic motion. Oil aerosols from screw or reciprocating compressors can accumulate, leading to 15-25% failure rates in high-cycle environments.

Coalescing filters at point-of-use stations remove these threats, extending tool life by 40% and minimizing unplanned downtime. For robotic assembly lines, where precision is paramount, filters achieving ISO 8573-1 Class 1 ensure consistent actuation, reducing defect rates in electronics or automotive parts.

Spray painting and powder coating demand contaminant-free air to prevent fisheyes, orange peel, or adhesion failures—issues that scrap up to 10% of finished goods. Water mist exacerbates corrosion in spray guns, while oil vapors contaminate paint media.

Positioned upstream of spray booths, coalescing elements strip aerosols to sub-trace levels, supporting high-volume transfer efficiency (HVLP) systems. In automotive plants, this translates to flawless finishes and compliance with VOC emission regs, slashing rework costs by 30%.

Hygiene is non-negotiable in food packaging, where compressed air contacts bottles, cans, or conveyor belts. Residual oil can foster bacterial growth, risking recalls under FDA or EU standards.

Coalescing filters in F&B lines deliver oil-free air (<0.01 mg/m³), protecting desiccant dryers from fouling and maintaining sterile blow-off processes. For aseptic filling, integrated with HEPA after-filters, they uphold Class 0 purity, boosting throughput while curbing microbial contamination risks.

Cleanrooms and hospital air systems require ultra-pure compressed air for nebulizers, dental tools, and drug mixing. Moisture and particulates can compromise sterility, leading to cross-contamination.

In these settings, coalescing filters precede adsorption dryers, achieving dew points of -40°C and oil contents below detection limits. This protects sensitive valves and cylinders, ensuring reliable performance in life-critical applications and aligning with ISO 8573 Class 1 medical grades.

Across broad piping networks, coalescing filters at main headers prevent widespread corrosion and energy loss from clogged lines. In large-scale plants, they handle flows up to 10,000 m³/h, integrating with SCADA for pressure monitoring.

For variable-demand systems, like those in pharmaceuticals, modular coalescers adapt to load swings, maintaining system-wide dryness and reducing compressor cycling by 15%.

Integrating coalescing filter elements into compressed air systems unlocks a cascade of returns, far outweighing initial investments.

| Benefit Category | Key Impacts | Quantifiable Gains |

|---|---|---|

| Economic | Cut maintenance and energy costs; extend equipment life | 15-25% OPEX reduction; ROI in 9-18 months; tool MTBF +40% |

| Environmental | Lower emissions and waste; support green certifications | Oil discharge <0.01 mg/m³; LEED/EU Ecodesign compliance; energy savings up to 20% |

| Reliability | Prevent failures in harsh conditions (e.g., humid tropics) | 30% fewer leaks; real-time monitoring via IoT sensors |

Potential hurdles, such as media blinding in dusty environments, are addressed with borosilicate upgrades or auto-drain valves. Overall, these filters foster leaner operations, with payback periods accelerated by Paier Filter's affordable, drop-in replacements.

Coalescing filter elements are more than accessories—they're strategic imperatives for any compressed air system striving for efficiency, compliance, and longevity. By vanquishing oil aerosols and moisture at the source, they shield your operations from costly disruptions, elevate product quality, and align with global sustainability goals. In an era of rising energy prices and regulatory scrutiny, investing in superior filtration isn't optional; it's essential.

For seamless upgrades without breaking the bank, turn to Paier Filter's coalescing filter element replacements—fully compatible with leading brands, backed by rigorous testing, and designed for hassle-free installation. Discover how our solutions can transform your compressed air performance today. Contact Paier Filter for a free consultation on "coalescing filters for compressed air systems" and step into a cleaner, more efficient future.