Natural gas remains a cornerstone of the global energy landscape, powering homes, industries, and transportation while serving as a transitional fuel toward renewables. According to the International Energy Agency (IEA), global natural gas demand is projected to hit 4.5 trillion cubic meters by 2025, underscoring the need for streamlined processing to meet this surge. However, from wellhead extraction to pipeline delivery, natural gas encounters numerous contaminants—aerosols, liquid droplets, fine mists, and micro-level particles—that can compromise pipeline quality, damage equipment, and escalate operational costs.

Enter coalescing filter elements, a pivotal technology in natural gas processing. These specialized filters excel at removing liquid aerosols and solid particulates, safeguarding compressors, meters, valves, and other vital components. By capturing both free liquids and entrained mists, coalescing filters minimize downtime, curb corrosion, and ensure consistent system performance. Unlike traditional methods like mechanical separators or adsorbents, which often suffer from high maintenance or inefficiency, coalescing filtration offers a smarter, more cost-effective approach.

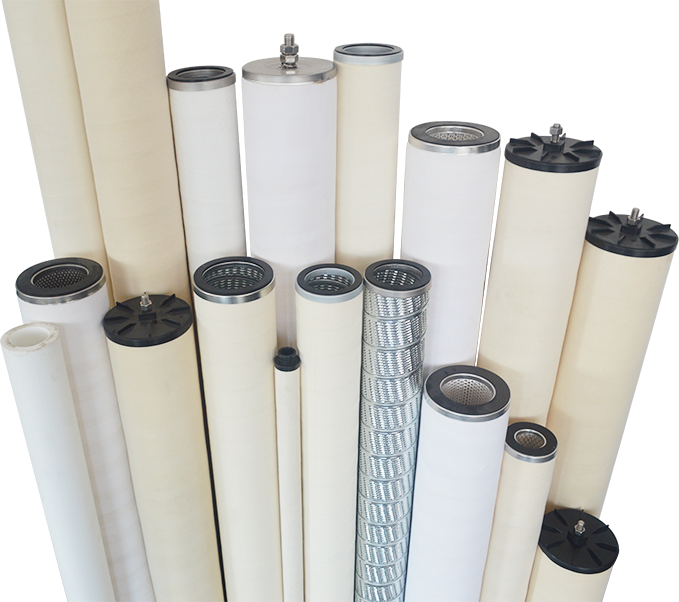

At the heart of effective natural gas filtration lies the science of coalescence—a process that merges tiny droplets into larger, separable ones. Coalescing filter elements are engineered media, typically crafted from borosilicate glass fibers, multi-layer polymers, or stainless steel mesh, designed specifically for gas-liquid separation.

The mechanism unfolds in three distinct phases:

Impingement (Capture): As contaminated natural gas flows through the filter media, inertial forces cause liquid droplets and solid particles to collide with and adhere to the fibers. These media feature pore sizes ranging from 0.1 to 10 microns, effectively trapping particles as small as 0.3 microns.

Coalescence (Merging): Captured micro-droplets attract each other via van der Waals forces and surface tension, forming larger droplets in a cascading "snowball" effect. This boosts separation efficiency, preventing fine mists from penetrating downstream.

Drainage (Separation): Gravity pulls the enlarged droplets to the filter's bottom, where they're drained via automated or manual outlets, yielding gas purity levels below 0.1 ppm liquid carryover.

What sets coalescing filters apart is their low pressure drop—often under 0.1 psi—minimizing energy consumption in high-volume systems. Per American Petroleum Institute (API) standards, top-tier coalescing elements achieve 99.99% droplet removal efficiency, outpacing conventional filters.

Structurally, these elements are multi-stage: an upstream pre-filter handles coarse debris, a central coalescing layer targets aerosols, and a downstream polish layer ensures ultra-clean output. Leading brands like Parker, PECO, and Facet offer standardized replacements compatible with various housings. For instance, Paier Filter provides premium natural gas-grade coalescing filter element replacements, utilizing imported glass fibers for durability in temperatures from -40°C to 150°C, all at a fraction of OEM costs.

Natural gas processing encompasses dehydration, acid gas removal, and liquefaction, each fraught with contamination risks. Coalescing filter elements integrate seamlessly across these stages, enhancing reliability and output.

From the wellhead, raw natural gas carries drilling fluids, condensate, and lube oil mists that threaten multistage compressors. Liquid ingress can cause "slugging," eroding impellers and bearings—issues accounting for over 30% of processing downtime, per industry reports.

Installed at compressor inlets, coalescing filters strip out liquid loads, averting damage in high-pressure environments (>1000 psi). They reduce water vapor to <10 ppm, extending mean time between failures (MTBF) by up to 30%. In shale gas operations, where variable flows are common, these filters maintain stable performance, slashing annual maintenance by 20%.

Dehydration is paramount to prevent hydrate formation and corrosion in pipelines. Triethylene glycol (TEG) or molecular sieve systems dominate, but upstream aerosols can foul glycol loops, spiking regeneration energy by 15%.

As pretreatment, coalescing elements remove free and entrained water, dropping liquid carryover from 100 ppm to under 1 ppm. On offshore platforms, Paier Filter's OEM-compatible elements—such as those mimicking PECO's VSS series—integrate effortlessly, boosting TEG efficiency and cutting chemical usage.

Sour gas containing H2S and CO2 requires amine sweetening (e.g., MEA or DEA units). However, oil-water emulsions from upstream processes contaminate amine solutions, leading to tray fouling and losses exceeding $50,000 annually per tower.

Positioned upstream of contactors, coalescing filters separate emulsions at the micron level, reducing fouling by 40% and extending amine life cycles. In mature fields with high chemical carryover, this application is crucial for compliance with emissions standards like those from the EPA.

Liquefied natural gas (LNG) demands dew points below -150°F, where even trace moisture ices heat exchangers. Coalescing filters at cold box inlets capture condensates and particulates, preserving heat transfer efficiency.

For modular skid-mounted units in remote fracking sites, compact designs from Facet ensure portability without sacrificing performance, raising uptime to near 99.5% and increasing throughput by up to 5%.

Post-processing, gas must meet ISO 8573.1 specs for long-haul transport. At custody transfer points, coalescing filters guard against meter fouling, preventing billing inaccuracies.

Handling flows over 500 MMSCFD with surge tolerance, Quad-series elements from Facet (and Paier equivalents) deliver sub-micron cleanliness, supporting high-stakes fiscal metering.

Adopting coalescing filter elements yields multifaceted advantages, aligning with the push for sustainable energy.

| Benefit Category | Key Impacts | Quantifiable Gains |

|---|---|---|

| Economic | Reduced downtime and maintenance; lower chemical/ energy use | 10-15% OPEX savings; ROI in 6-12 months; MTBF +30% |

| Environmental | Minimized VOC emissions and corrosion; extended asset life | VOC <5 ppm; EPA/REACH compliance; supports net-zero goals |

| Operational | Enhanced reliability in extremes (e.g., -50°C Arctic ops) | 20% fewer inspections; predictive maintenance via sensors |

Challenges like media saturation in high-silicon environments are mitigated with PTFE coatings or differential pressure monitors, ensuring longevity.

In the intricate web of natural gas processing, coalescing filter elements stand as vigilant sentinels, ensuring purity from source to sink. They address immediate threats like corrosion and fouling while paving the way for efficient, low-emission futures. For operators eyeing cost reductions without performance trade-offs, explore Paier Filter's premium replacements for Parker, PECO, and Facet—delivering unmatched value.

Ready to optimize your filtration? Contact Paier Filter today for expert guidance on "coalescing filter elements in natural gas processing." Secure your energy infrastructure and drive sustainable growth.