Oil-water separation plays a crucial role in industrial processes ranging from petrochemical refining and power generation to wastewater treatment and marine operations. The ability to efficiently separate oil from water not only protects downstream equipment but also ensures compliance with environmental discharge standards. Over the years, a variety of mechanical, chemical, and physical separation techniques have been developed, each tailored to specific contamination levels, flow rates, and oil droplet sizes.

Gravity separation is one of the oldest and simplest methods used to remove oil from water. It relies on the natural density difference between oil and water—oil droplets, being lighter, rise to the surface while water settles below. Devices such as API separators and parallel plate interceptors enhance this effect by providing a large settling area.

However, gravity separation is only effective for relatively large oil droplets (usually >150 microns) and stable flow conditions. It’s often used as a primary treatment step before finer separation methods.

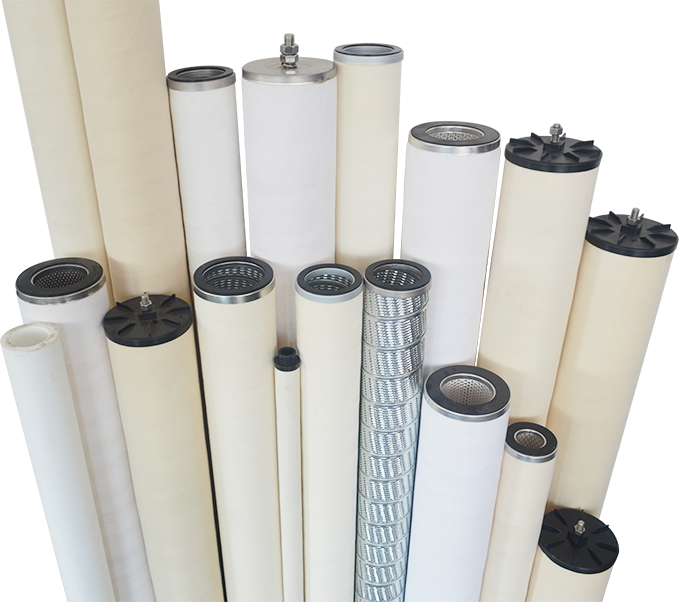

Coalescing separation is widely used for finer droplets that gravity systems cannot remove. In this process, small dispersed oil droplets collide and merge (coalesce) into larger ones, which then rise more easily to the surface.

Coalescing media—typically glass fiber, polyester, or specialized filter materials—create conditions that encourage droplet merging. This principle is applied in both oil-water coalescing filters and gas-liquid coalescers, enabling efficient removal of oil aerosols and mist from fluids or air streams.

The coalescing method is valued for its high efficiency, compact design, and compatibility with continuous industrial systems such as compressor discharge, turbine lubrication, and hydraulic oil purification.

Centrifugal separation uses rotational forces to accelerate the natural separation of oil and water. When a contaminated fluid is spun at high speed, the heavier water phase moves outward while the lighter oil collects near the center.

Centrifuges are particularly effective for emulsified mixtures or when high throughput is required. Their main drawbacks are energy consumption, maintenance costs, and mechanical complexity.

Modern oil-water separation technologies increasingly rely on membrane filtration and adsorbent materials.

Membrane filters use microfiltration or ultrafiltration membranes to physically block oil droplets. They provide high purity but require regular cleaning to prevent fouling.

Adsorbent materials, such as oleophilic fibers and activated carbon, trap oil molecules through surface attraction. These are ideal for polishing treatment or recovering trace oil from wastewater.

These advanced methods are especially important in industries with strict discharge limits, like food processing, pharmaceuticals, and offshore platforms.

In practice, multiple separation techniques are often integrated to achieve the best results. For example, a system might use gravity separation for bulk removal, followed by coalescing filtration for smaller droplets, and membrane filtration for final polishing. The right configuration depends on the oil concentration, flow rate, and operational cost targets.

Oil-water separation remains a fundamental process across many industrial sectors. As environmental regulations tighten and operational standards rise, coalescing filtration continues to grow in importance due to its efficiency and compact design.

At the forefront of replacement coalescing filter solutions, Hebei Paier Filtration Equipment Technology Co., Ltd. offers high-quality equivalent cartridges. Paier's replacement coalescing elements deliver reliable separation performance at a lower cost, supporting industries in maintaining clean fluids and sustainable operations.