In compressed air systems, the coalescing filter element (also known as a coalescer cartridge or oil mist separator) plays a vital role in removing oil aerosols, water droplets, and fine particles from the air stream. By using coalescence principles, it ensures clean, dry compressed air essential for pneumatic tools, manufacturing processes, and sensitive applications like food production or painting.

However, during operation, coalescing filter elements often encounter issues that reduce efficiency, increase energy costs, and cause downtime. This article explores the most common problems, their causes, symptoms, and practical solutions to help you maintain optimal system performance.

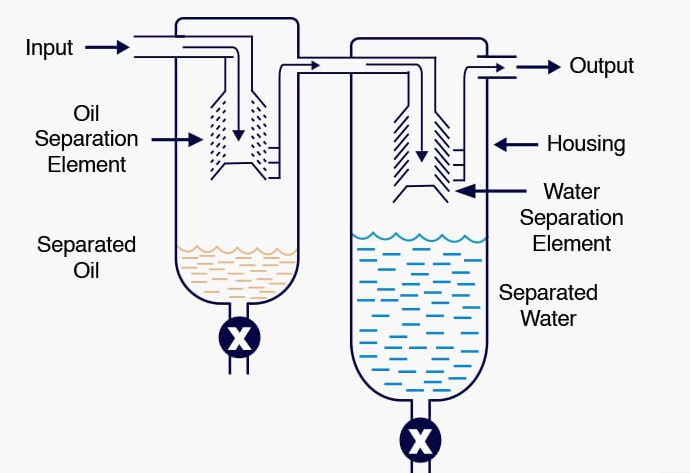

Coalescing filters typically feature multi-layered borosilicate glass microfiber media. Compressed air flows from inside to outside (inside-out flow), where tiny oil and water droplets collide with fibers, coalesce into larger droplets, and drain to the bottom for automatic discharge.

This illustration shows the internal structure and working principle of a typical coalescing filter element, highlighting the coalescence process.

High-efficiency coalescing filter elements can reduce residual oil content to below 0.01 ppm.

One of the earliest and most common indicators of trouble is a gradual or sudden increase in differential pressure (ΔP). This forces the compressor to work harder against the restriction, directly translating to higher electricity consumption—typically 0.5-1% more energy per 1 psi (0.07 bar) increase in pressure drop.

Detailed Causes:

Progressive buildup of solid particulates, oil sludge, varnish, or condensed water on the filter media.

Inadequate or delayed replacement of upstream pre-filters (e.g., general-purpose particulate filters), allowing excessive contaminants to reach the coalescer.

High ambient humidity combined with poor aftercooler performance, leading to liquid condensate overload.

Use of incompatible or degraded compressor lubricant that forms sticky deposits or emulsifies with water.

Operating in dusty environments without proper intake filtration.

Symptoms and Detection:

Rising readings on the differential pressure gauge or indicator.

Compressor alarms for high pressure drop.

Reduced system airflow or slower tool response.

Consequences:

Skyrocketing energy bills.

Overheating of the compressor.

Premature failure of other components.

Differential pressure gauges are essential monitoring tools—install them if your system lacks one.

Oil contamination downstream is a serious issue that can ruin finished products, damage pneumatic equipment, or violate air quality standards (e.g., ISO 8573-1 Class 1 requires <0.01 mg/m³ oil).

Detailed Causes:

Filter media saturation after prolonged use or liquid slugging.

Physical damage to the media (tears, collapses) from pressure surges or improper handling.

Blocked or incorrectly installed scavenge tube, preventing drained oil from returning.

Faulty minimum pressure valve or check valve in the separator tank.

Excessive operating temperatures (>100-110°C) causing oil vaporization.

Wrong filter grade (e.g., using a coarse coalescer for fine filtration needs).

Re-entrainment due to high air velocity or low separator tank level.

Symptoms and Detection:

Oily residue in air lines, tools, or end products.

Frequent downstream filter clogging.

Unusual oil consumption without visible leaks.

Consequences:

Product spoilage in food/pharma industries.

Corrosion or seizure in pneumatic cylinders/valves.

Costly rework or recalls.

The filter media can become irreversibly blocked or structurally compromised, rendering it ineffective.

Detailed Causes:

Chronic exposure to high contaminant loads without upstream protection.

Sudden liquid slugs from faulty drains or aftercoolers.

Rapid system pressurization during startup shocking the wet media.

Chemical incompatibility between lubricant additives and filter materials.

Poor storage/handling leading to pre-installation damage.

Symptoms and Detection:

Visible discoloration or deformation upon inspection.

Combined high ΔP and oil carryover.

Consequences:

Complete loss of filtration efficiency.

Risk of media fragments entering the airstream.

Unexplained high oil usage often points to poor coalescence.

Detailed Causes:

Inefficient separation allowing oil aerosols to escape.

Scavenge line restrictions or check valve failures.

Overfilled oil level causing foaming.

Symptoms:

Frequent oil top-ups.

Low oil level alarms.

Microbial growth in persistently wet elements (relevant for breathing air systems).

Bypass due to damaged O-rings or improper seating during installation.

Premature failure from counterfeit or low-quality replacement elements.

To minimize these problems:

Monitor differential pressure daily and replace elements at 6-12 months or when ΔP reaches 8-12 psi.

Maintain upstream filters rigorously and use OEM-recommended lubricants.

Ensure proper drainage, slow startups, and good ventilation.

Invest in high-quality replacements with robust media and drainage layers.

At Paier Filter, our coalescing filter elements are engineered with premium multi-layer media for exceptional efficiency, minimal pressure drop, and robust resistance to common failures. As direct replacements for major brands, they help you avoid costly issues while extending service life.

Explore our range at www.paierfilter.com or contact us for tailored recommendations. Keep your compressed air clean and reliable—choose Paier Filter today!