Parker coalescing filter cartridges are engineered to deliver exceptional efficiency in removing liquid aerosols, fine mists, and oil contaminants from air, gas, and liquid systems. They are widely applied in compressed air systems, natural gas processing, and lubrication systems, where clean and dry output is essential for safe and reliable equipment operation. Understanding how these cartridges work provides valuable insight into the science behind high-performance separation.

Coalescing filtration relies on two physical processes—diffusion and interception—to capture and merge small liquid droplets. As a gas or liquid stream passes through the filter media, tiny droplets collide with the fibers and combine into larger droplets. These larger droplets then migrate along the fibers and are drained away by gravity.

This mechanism makes coalescing filters ideal for separating fine oil aerosols from compressed air or removing water mist from hydrocarbons in gas treatment systems.

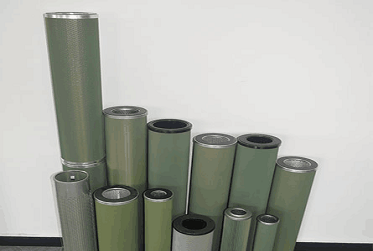

A Parker coalescing cartridge typically features multiple layers of microfiber media. The inner layer captures fine aerosols, the middle layer supports coalescence and drainage, and the outer layer acts as a protective shell to prevent re-entrainment of collected droplets.

The layered design ensures:

High capture efficiency (often exceeding 99.9% for droplets >0.3 microns)

Minimal pressure drop, even at high flow rates

Long service life through optimized drainage paths

Coalescing filter cartridges are critical components in:

Compressed air systems, to remove oil carryover and protect downstream equipment.

Natural gas processing, for eliminating entrained liquids before metering and compression stages.

Hydraulic and lubrication systems, where water and oil mist can degrade performance and accelerate wear.

Chemical and petrochemical industries, to maintain purity and prevent catalyst contamination.

In each case, Parker filters provide consistent, high-efficiency separation that meets the strict purity demands of modern operations.

Coalescing filters offer several benefits over traditional mechanical separators:

Compact design: Saves installation space while maintaining high throughput.

Consistent performance: Unaffected by flow direction or minor pressure fluctuations.

Environmental protection: Enables clean discharge and oil recovery for reuse.

Lower maintenance costs: Extended service intervals reduce downtime.

These features make them indispensable in advanced process systems that demand reliability and efficiency.

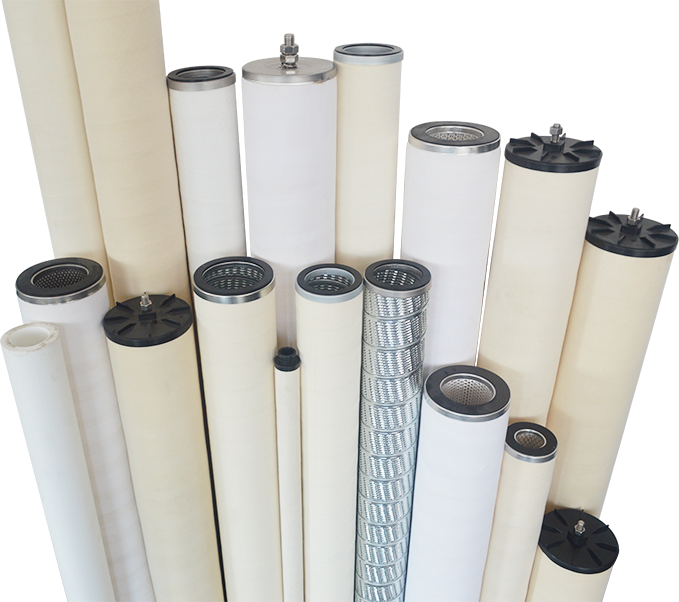

To maintain optimal separation efficiency, coalescing filter elements must be replaced at recommended intervals. Using high-quality replacement elements that match Parker specifications ensures proper fit, consistent performance, and protection for downstream equipment.

Parker coalescing filter cartridges exemplify the precision engineering behind efficient gas-liquid and oil-water separation. By leveraging multi-layer microfiber construction and advanced coalescing principles, these filters provide exceptional purity, extended life, and reliable system protection.

For industries seeking reliable and cost-effective replacements, Hebei Paier Filtration Equipment Technology Co., Ltd. supplies premium-quality equivalents to Parker coalescing filter cartridges. Engineered for compatibility and performance, Paier's replacement elements offer dependable separation efficiency at a lower cost—helping you achieve clean fluids and sustained productivity.